– With thanks to Harry F. Mathews and his Harry’s Old Engine website for permission to reprint this old information on how to fire-up the old Fairbanks Morse gasoline engines of the 1900s.

The following text is borrowed with permission from Harry’s Old Engine website. I never had the chance to work with these monstrous engines and found this information very interesting and wanted to pass it on here. Remember, he is referring to a farm engine, but I imagine the lighthouse engines were also close to 32 Hp.

“The hit of the show as far as I was concerned was a 32 Horsepower Fairbanks Morse Engine. This is hit and miss, 11,000 pounds of iron from 1905 that came from a feed mill in Kentucky. Its power was rated at 200 r.p.m., but it was slowed down considerably, so much so that you’d think it was going to stop just as it fired.”

“The hit of the show as far as I was concerned was a 32 Horsepower Fairbanks Morse Engine. This is hit and miss, 11,000 pounds of iron from 1905 that came from a feed mill in Kentucky. Its power was rated at 200 r.p.m., but it was slowed down considerably, so much so that you’d think it was going to stop just as it fired.”

“This engine is started with a kitchen match! A kitchen match is loaded into a special plunger (see photo) and then screwed into a portal on the side of the combustion chamber. Note the extra matches lying on the side. With safety matches being modern, I’ll bet these “strike anywhere”: types are getting scarce.”

“This engine is started with a kitchen match! A kitchen match is loaded into a special plunger (see photo) and then screwed into a portal on the side of the combustion chamber. Note the extra matches lying on the side. With safety matches being modern, I’ll bet these “strike anywhere”: types are getting scarce.”

“After rotating the flywheel to bottom dead center of the compression stroke, you then fill the primer cup with a “calculated” amount of gasoline along with a little in the match hole for good measure. Now screw the match holder into the match light portal, hop up on the flywheel and give a good heave-ho in the reverse direction to compress the charge.”

“After rotating the flywheel to bottom dead center of the compression stroke, you then fill the primer cup with a “calculated” amount of gasoline along with a little in the match hole for good measure. Now screw the match holder into the match light portal, hop up on the flywheel and give a good heave-ho in the reverse direction to compress the charge.”

“Next, hop off at just the right time and hit the match plunger.”

“BLAM!!!! and away it goes!”

“This engine is owned by Lew Donaldson of Dade City, FL (Or does it own him? We are all only caretakers.) I expect we’ll see Lew at the Florida Flywheelers’ shows up at the new Flywheeler park between Ft. Meade and avon park, FL. I look forward to seeing it again and pestering Lew for more information such as bore and stroke, crank diameter, etc. It was neat to either figure out all the parts and what they were for or if not, ask about them.”

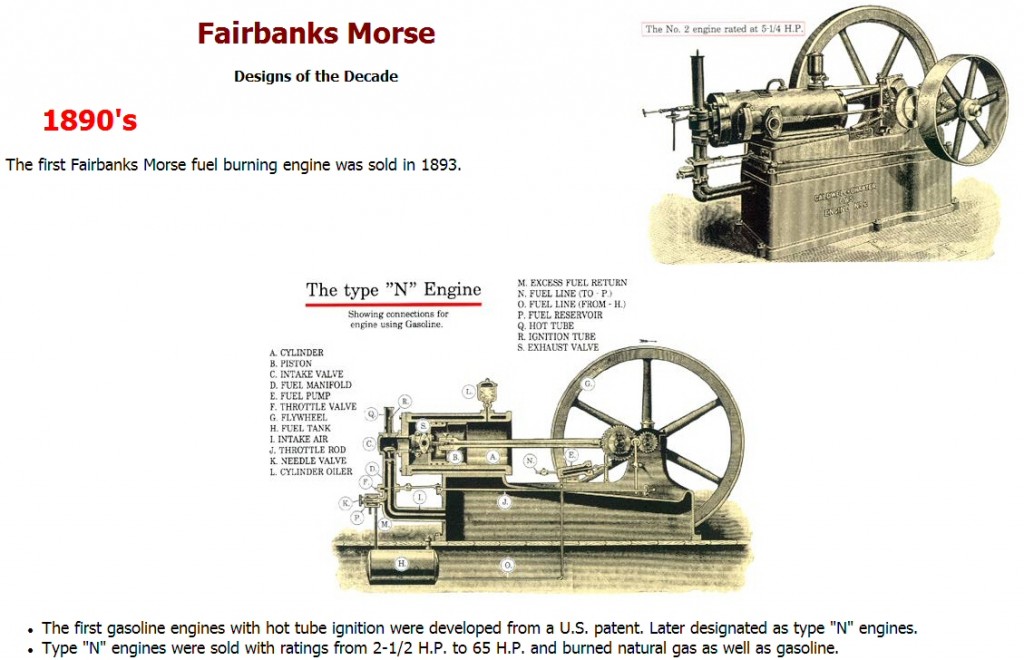

“A whole series of type “N” engines evolved around this design, including match start. By the way, if you didn’t want to deal with the match, you could always have someone trip the igniter. The problem is that you’d better trust both the igniter tripper and your own instincts of when to jump off! For the more cautious, there is a hand pump on the side that will pump a mixture of air and fuel into the combustion chamber while you hold the flywheel from turning. The ignitor or match can then be tripped to set off the mix.”

“Once rolling, you then have to mess with the fuel mix to get it to keep rolling and not smoke up the place at the same time. For running kerosene, a metal flex-pipe is connected from below the exhaust port to the base of the fuel mixer to preheat the fuel. Oilers are provided for the rings and an additional oiler feeds a slinger ring that is chambered through to the crankpin. These engines were designed to provide uninterrupted service over long periods.”

[nggallery id=38]

The following video is not a Type “N” but a Type “Y”. It is also not gasoline driven but oil (probably a form of diesel oil) and it is started by heating up the head (like the electrical glow plugs of yesteryear) but it shows how difficult it was to fire-up one of these monsters. The gasoline version would not require the pre-heating as gasoline is more volatile than oil. Note how the flywheel is spun counter-clockwise against the compression of the engine to get it to spin. The engine actually turned clockwise as you can see when it starts.